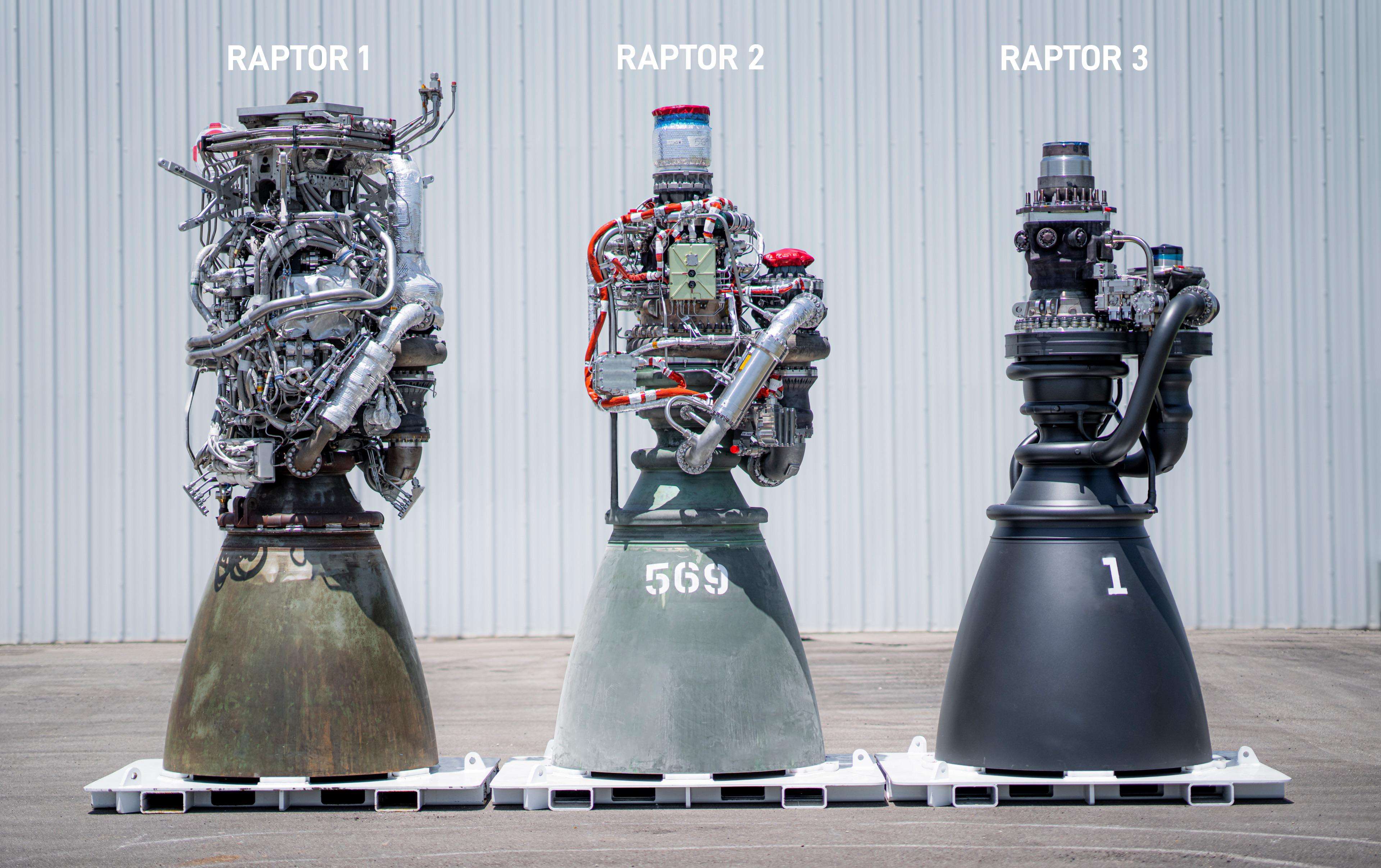

Including the Deep Blue Aerospace Example with the 85% 3D-Printe

Introduction Aerospace has always been an industry defined by extremes: extreme environments, extreme precision, and extreme cost sensitivity. Over the past decade, additive manufacturing (3D printing) has moved from a prototyping tool to a core

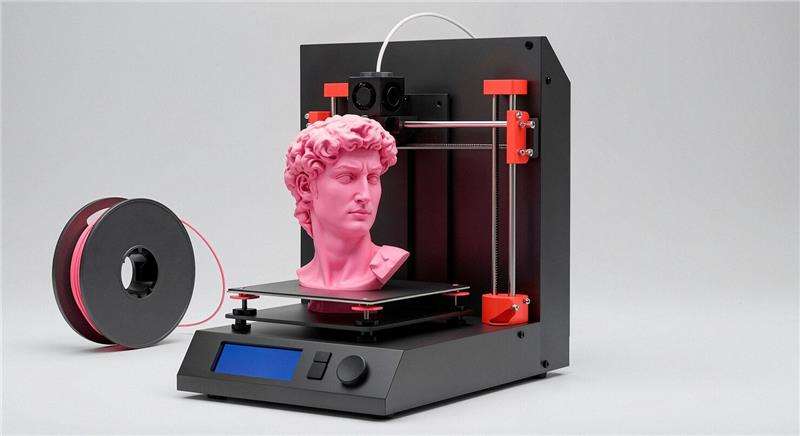

3D printing has advanced far beyond simple plastic prototyping. Today, industrial additive manufacturing supports an incredible range of materials including metal, resin, composites, and even bio-compatible materials used in medical applications. As the technology continues advancing, the future

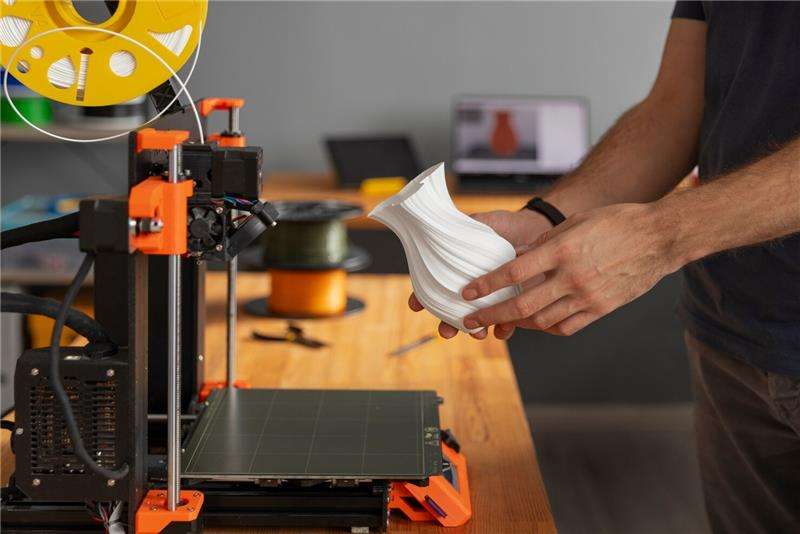

Product development is a fast-paced process, and staying ahead means shortening the time between idea and final product. That’s where professional 3D printers become an essential tool. Instead of outsourcing every prototype, companies can bring the entire process in-house and take control o

For decades, industrial manufacturing has relied on slow prototyping processes, expensive tooling, and lengthy production timelines. Today, 3D printing is breaking that cycle and reshaping the way companies bring products to life. With advanced 3D printing machines, manufacturers can now design,