How 3D Printing Technology Is Applied to Aerospace: A Clear and Quantified Overview

Including the Deep Blue Aerospace Example with the 85% 3D-Printed Thunder-RS Engine

1. Introduction

Additive manufacturing (commonly known as 3D printing) has shifted from prototyping to mission-critical aerospace production. Its capacity to create complex geometries, consolidate assemblies, reduce lead time, and optimize structural performance has made it foundational in modern rocket engine and spacecraft development. This article explains how 3D printing is applied in aerospace, with a detailed example of how Deep Blue Aerospace leveraged it to manufacture the Thunder-RS engine, where over 85% of components are 3D printed. (搜狐)

2. Why Aerospace Needs 3D Printing

Aerospace components must meet exceptionally high standards for strength, precision, and reliability. Traditional manufacturing methods (casting, machining, welding) often struggle with:

- Internal fluid pathways

- Thin-wall or complex cooling channels

- Multi-material integration

- Short production cycles

3D printing overcomes these constraints by building parts layer by layer, enabling:

- Topology optimization and weight reduction

- Part consolidation (multiple components become one)

- Rapid design iteration

- Reduced tooling cost

These advantages translate to lower mass, higher performance, and faster time to flight readiness.

3. Common Aerospace Applications of 3D Printing

3.1 Rocket Engines and Propulsion Systems

Rocket engines have hundreds of parts with precise flow passages and thermal requirements. 3D printing allows integration of cooling channels, injectors, and complex manifolds that would be extremely difficult or impossible to machine traditionally.

Typical parts produced by additive printing include:

- Combustion chambers

- Turbopump housings and impellers

- Injector assemblies

- Thrust chambers

- Valves and actuator components

This leads to engines that are lighter, more compact, and easier to qualify for spaceflight.

3.2 Structural Components

Beyond propulsion, structural components are printed to reduce assembly complexity while maintaining strength:

- Brackets and mounts

- Heat exchangers

- Satellite support structures

- Lightweight lattices for thermal management

4. Case Study: Deep Blue Aerospace and the Thunder-RS Engine

Company Background

Deep Blue Aerospace is a Chinese commercial aerospace company focusing on reusable rocket systems and liquid-fuel engines. The company has actively integrated metal additive manufacturing into its propulsion and structural design workflow since its early development stages. (3dprint.com)

Thunder-RS Engine Overview

The Thunder-RS engine is a high-performance liquid oxygen (LOX) and kerosene rocket engine designed for reusability and cost efficiency. Key specifications include:

- Thrust at sea level: approximately 1240 kN (about 130 metric tons) (搜狐)

- Thrust-to-weight ratio: > 150 (搜狐)

- Throttle range: 50% to 110% (搜狐)

Additive Manufacturing: 85% 3D Printed

Over 85% of the engine’s components are manufactured using 3D printing processes, primarily metal powder-bed fusion and other industrial metal additive techniques. This extensive use of additive manufacturing spans:

- Turbopump components: housing, impeller, inducer, turbine casing, turbine stator (NASA航天飞行论坛)

- Valves: main oxygen and kerosene valves printed in high-temperature alloy and titanium alloy casings (NASA航天飞行论坛)

- Structural housings and manifolds: consolidated parts that eliminate multiple machining setups and weld joints (搜狐)

This level of integration dramatically reduces part count and assembly steps, decreases weight, and enhances performance consistency.

Example: Combustion Chamber Innovation

Deep Blue Aerospace has printed combustion chamber components with dimensions such as:

- Height: ~780 mm

- Diameter: ~550 mm

These chambers incorporate internal cooling features, lattice structures, and self-supporting geometries that would be challenging to produce with conventional methods. The use of additive manufacturing also accelerated design verification cycles by roughly 80% compared to traditional processes. (3dprint.com)

5. Benefits Realized by Deep Blue Aerospace

The deep integration of 3D printing in engine manufacture delivers clear operational advantages:

Benefit

Explanation

Weight reduction

Fewer discrete parts and optimized geometries lower engine mass

Lead time reduction

Complex parts previously requiring months of machining can be printed in days

Cost savings

Reduced machining setup and fewer assemblies lower production cost

Improved reliability

Reduced welds and joints decrease potential failure points

6. Broader Aerospace Impact

While Deep Blue Aerospace provides a concrete example, aerospace leaders worldwide apply additive manufacturing for:

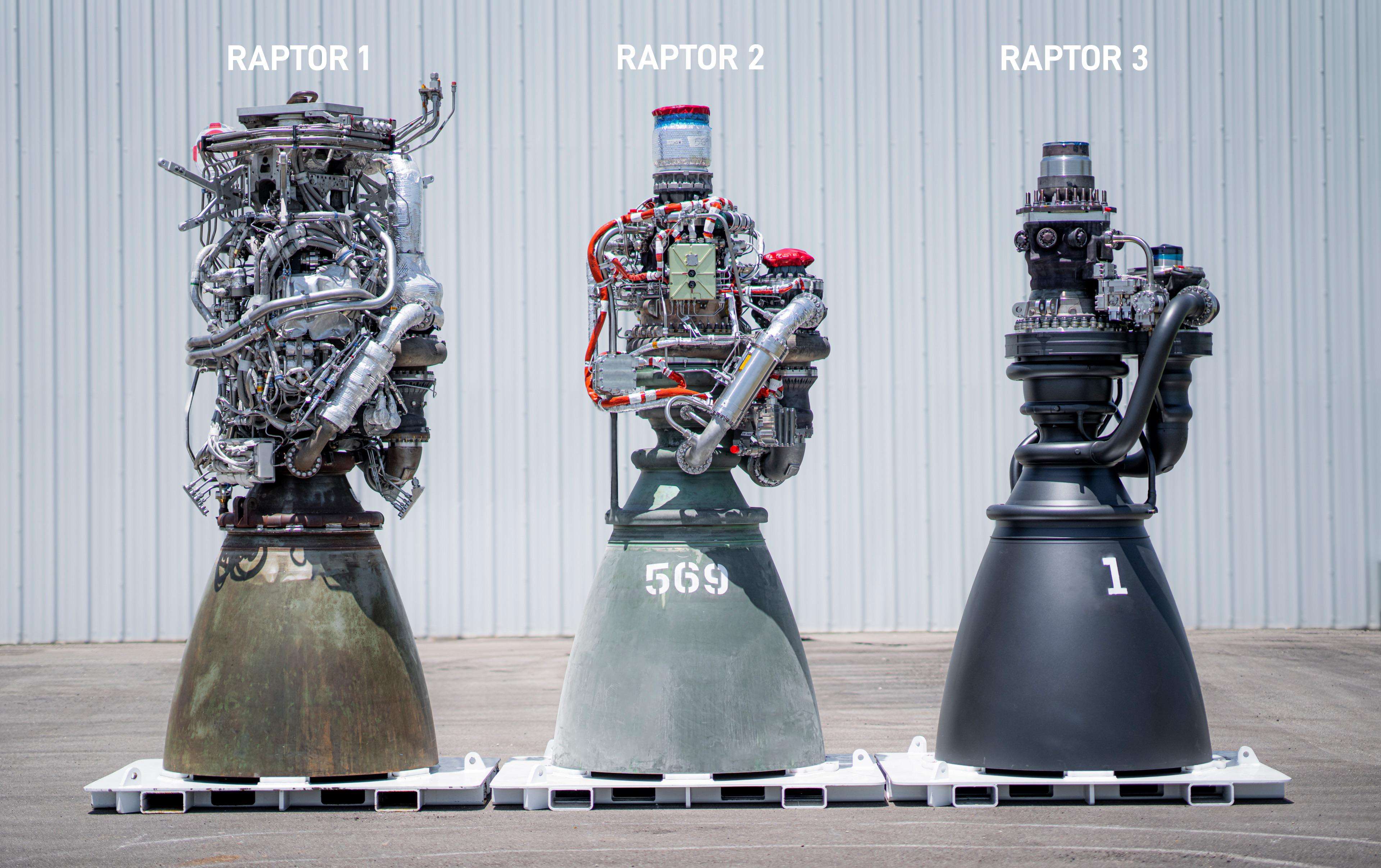

- SpaceX Raptor engines: major structural parts are 3D printed and integrated

- NASA propulsion tests: 3D printed combustors and heat exchangers used in R&D programs (NASA)

- Commercial airframes: lightweight structural brackets and panels

- Satellite systems: integrated payload support structures

The trend is clear: 3D printing is transitioning from supplementary to foundational production technology in aerospace.

7. Conclusion

Additive manufacturing is fundamentally reshaping aerospace design and production. By enabling part consolidation, reducing lead time, and unlocking new performance levels, 3D printing is no longer an optional tool but a strategic technology for propulsion systems and launch vehicles.

Deep Blue Aerospace’s 85% 3D-printed Thunder-RS engine exemplifies how deeply additive manufacturing can be integrated into a complex aerospace product. This example demonstrates not only technical feasibility but also operational advantages in building next-generation reusable systems.