How 3D Printing Is Transforming Aerospace Manufacturing

Introduction

Aerospace has always been an industry defined by extremes: extreme environments, extreme precision, and extreme cost sensitivity. Over the past decade, additive manufacturing (3D printing) has moved from a prototyping tool to a core production technology in aerospace. Today, it is reshaping how engines are designed, manufactured, qualified, and scaled.

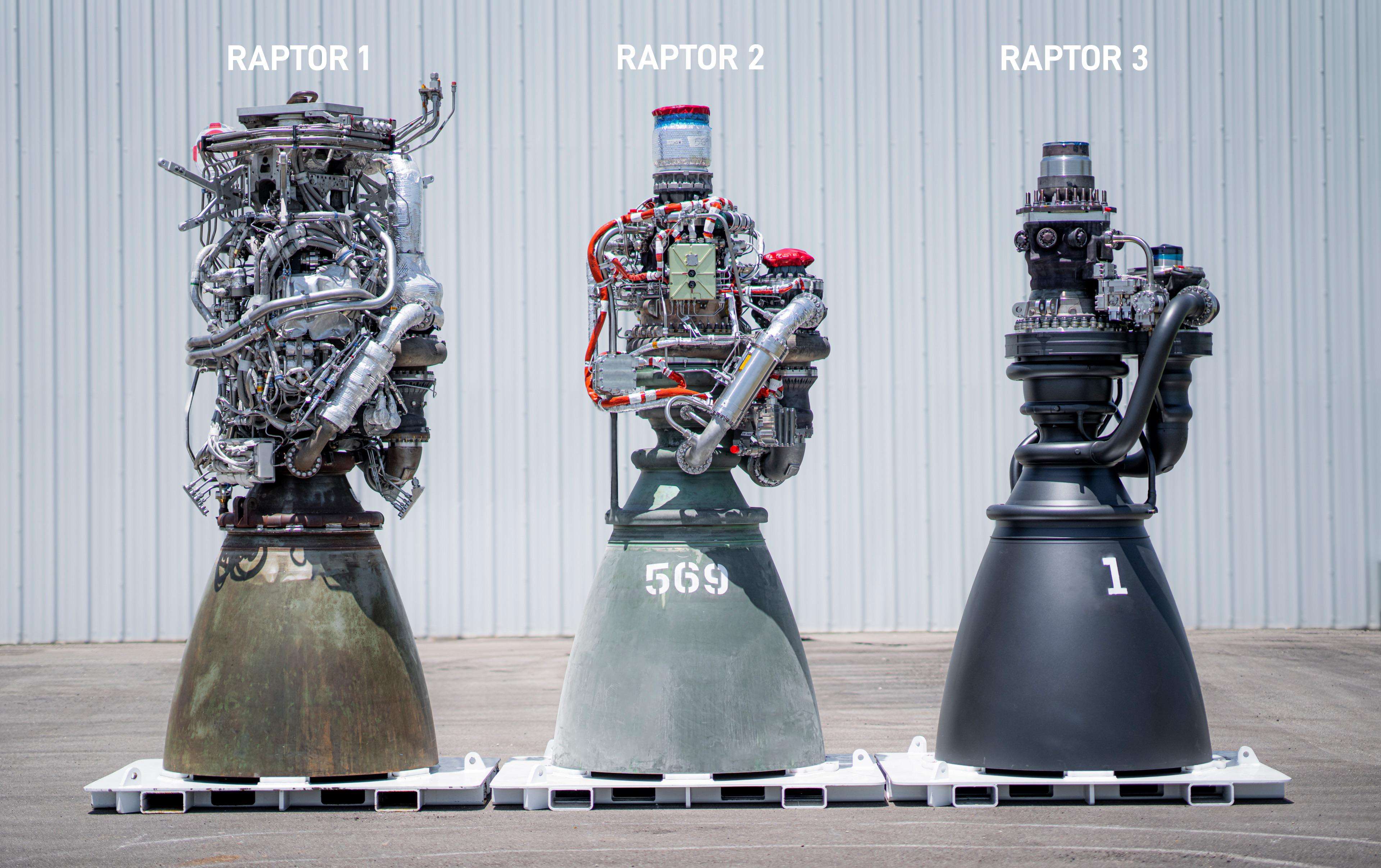

Among the most compelling examples is SpaceX’s Raptor rocket engine, particularly the latest Raptor 3, which demonstrates how deep integration of 3D printing can fundamentally simplify one of the most complex machines ever built.

Why Aerospace Was a Natural Fit for 3D Printing

Aerospace manufacturing has several characteristics that align exceptionally well with additive manufacturing:

- Low-volume, high-complexity parts

- Demand for weight reduction

- Extreme performance requirements

- High cost of tooling and long lead times

- Continuous iteration and design evolution

Traditional subtractive manufacturing struggles with internal channels, organic geometries, and part consolidation. 3D printing, by contrast, enables geometry-first design, where performance is optimized before manufacturability constraints are imposed.

Key Applications of 3D Printing in Aerospace

1. Engine Components with Internal Complexity

Rocket and jet engines require intricate internal cooling channels, fuel manifolds, and lattice structures. Metal 3D printing enables:

- Regenerative cooling channels inside combustion chambers

- Integrated injector heads

- Optimized flow paths are impossible to machine conventionally

This directly improves thermal efficiency, durability, and thrust-to-weight ratio.

2. Part Consolidation and Assembly Reduction

One of the most significant advantages is part consolidation:

- Dozens or even hundreds of individual parts can be printed as a single component

- Fewer welds, bolts, and joints

- Reduced failure points and inspection steps

This has a cascading effect on reliability, production speed, and cost.

3. Faster Design Iteration Cycles

Additive manufacturing dramatically shortens the design–test–iterate loop:

- Design changes can be implemented in days instead of months

- No retooling required

- Rapid validation through hot-fire and flight testing

This speed advantage is critical for companies pursuing aggressive development timelines.

SpaceX Raptor Engines: A Case Study in Additive-Driven Design

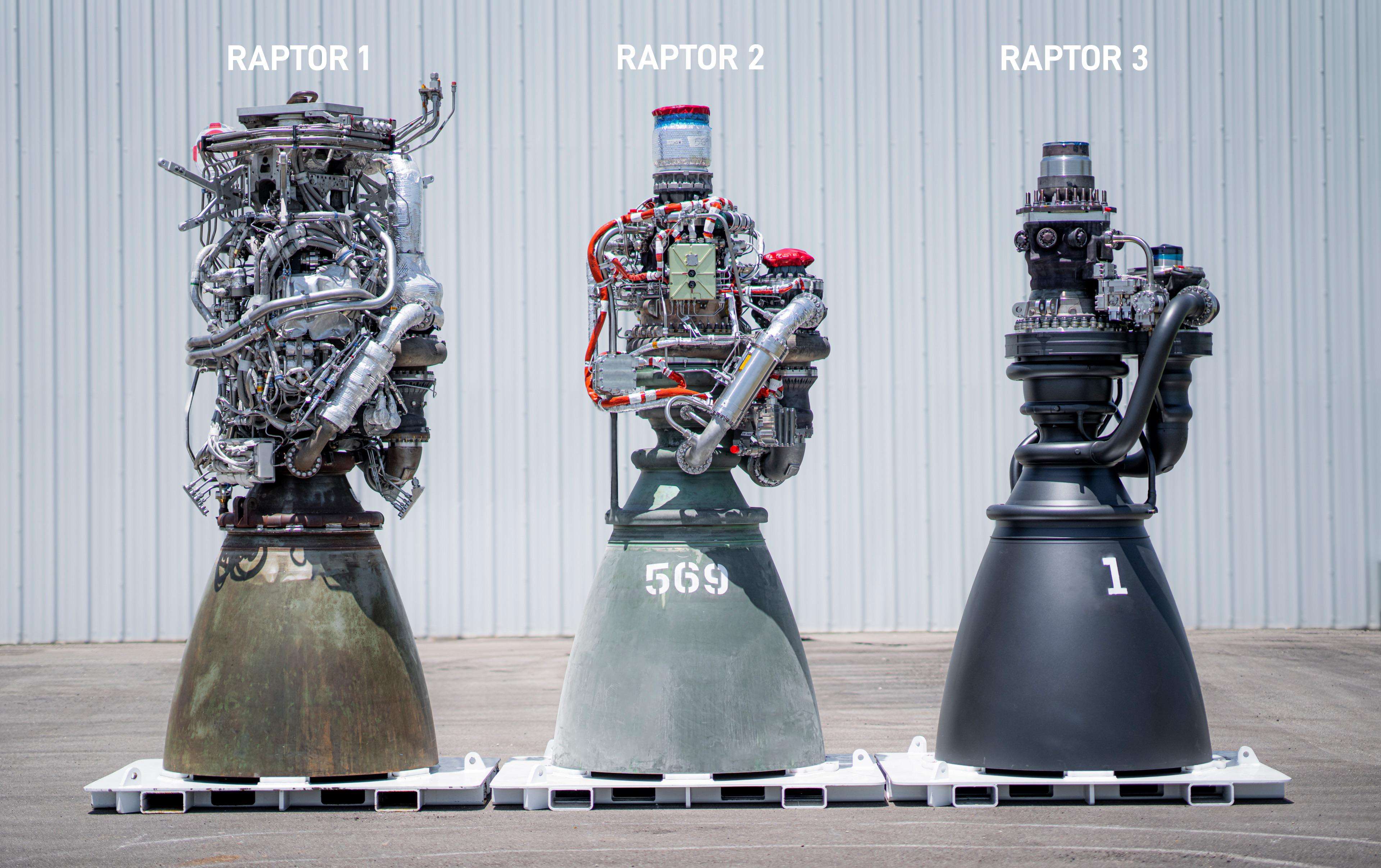

Raptor 1 and Raptor 2: Performance Through Complexity

The Raptor engine is a full-flow staged combustion methane engine, one of the most complex rocket engine cycles ever put into production.

- Raptor 1 demonstrated technical feasibility but was highly complex, with many discrete parts and manufacturing steps.

- Raptor 2 improved thrust and reliability, but still relied on a relatively intricate assembly architecture.

While both versions used 3D-printed components extensively, their designs were still influenced by legacy manufacturing assumptions.

Raptor 3: Design Simplified by Additive Manufacturing

Instead of using 3D printing merely to manufacture complex designs, SpaceX used it to eliminate complexity altogether.

Key improvements widely observed and discussed in the industry include:

- Significant reduction in visible piping and external plumbing

- Greater internal integration of fluid channels

- Fewer welded joints and interfaces

- Cleaner, more compact engine layout

In essence, many subsystems that previously existed as external assemblies were absorbed into printed structures.

The result:

- A lighter engine

- Fewer failure points

- Faster production

- Easier inspection and maintenance

- Lower unit cost at scale

This is not incremental optimization—it is architectural simplification enabled by additive manufacturing.

Why Raptor 3 Matters to the Aerospace Industry

Raptor 3 illustrates a broader trend:

3D printing is no longer just a manufacturing method; it is a design philosophy.

The implications extend beyond SpaceX:

- Design for Function, Not for Tooling

Engineers are no longer constrained by what can be milled or cast. - Manufacturing Scalability with Fewer Dependencies

Reduced reliance on complex supply chains and specialized tooling. - Reliability Through Simplicity

Fewer parts often outperform highly optimized but fragile assemblies. - Cost Reduction Through Learning Curves, Not Outsourcing

Costs fall as printing processes mature and production volume increases.

The Broader Aerospace Impact

Beyond rocket engines, additive manufacturing is now widely used for:

- Structural brackets and mounts

- Heat exchangers

- Satellite components

- UAV airframes

- Tooling, jigs, and fixtures

Major aerospace organizations—including SpaceX, NASA, Airbus, Boeing, and leading engine manufacturers—are actively expanding qualified 3D-printed flight hardware.

Conclusion

The evolution from Raptor 1 to Raptor 3 demonstrates the true power of 3D printing in aerospace:

Not making complex parts easier to build, but making complex systems fundamentally simpler.

As metal additive manufacturing continues to mature, aerospace companies that treat 3D printing as a core design enabler, rather than a secondary process, will define the next generation of propulsion systems and flight hardware.

In aerospace, simplicity is not a compromise—it is a competitive advantage.