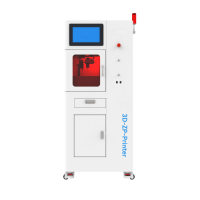

Product Description:

High Precision Mirror EDM Machine

A EDM machine with mirror finishing, hard alloy, graphite processing efficiency and the most cost-effective.

Features :

- High precision mirror machine.

- Automatic lifting of oil tank.

- Windows control system (multilingual).

- Network transmission port.

- PIKA ultra-precision mirror discharge circuit.

- Spark oil constant temperature device.

- 60 workpiece coordinate systems.

Special Option :

- C axis.

- 16-position ATC electrode library.

- Stabilizer.

- Quick Chuck.

|

Item |

Unit |

AR50 |

AR65 |

|

Table size (length x width) |

mm |

700x450 |

850x600 |

|

X, Y, Z axis travel |

mm |

500x400x300 |

650x450x350 |

|

Liquid tank internal size (L x W x H) |

mm |

870x620x350 |

900x700x350 |

|

Max. electrode weight |

kg |

50 |

50 |

|

The Max. and Min. distance from worktable surface to electrode plate |

mm |

200-500 |

200-550 |

|

Positioning accuracy (JIS standard) |

5µm/Arbitrarily 300mm |

||

|

Repeat accuracy (JIS standard) |

µm |

2 |

2 |

|

Machine weight |

kg |

5500 |

6500 |

|

Reservoir tank volume |

L |

300 |

400 |

|

Dimensions (length x width x height) |

mm |

2100x2000x2400 |

2350x2380x2500 |

|

Processing fluid filtration method |

Switching Cartridge Filter |

||

|

Numerical control pulse power supply device |

40A |

||

|

Maximum machining current |

A |

40 |

40 |

|

Total input power |

KVA |

9 |

9 |

|

Input power |

380V(china) |

||

|

Best surface roughness |

Ra0.1µm |

||

|

Minimum electrode loss |

0.1% |

||

|

Highest productivity |

Copper hit steel 500 mm²/min, Graphite hit steel 1000 mm²/min |

||

|

Standard process |

Copper/steel, fine copper/steel, graphite/steel, copper/tungsten/steel, fine copper tungsten/steel, steel/steel, copper/tungsten alloy/steel, copper/aluminium, graphite/hard alloy, copper-tungsten alloy/steel, red copper/red copper |

||

|

Interpolation type |

Linear, circular, spiral |

||

|

Compensation for each axis |

Each axis respectively step error compensation, clearance compensation |

||

|

Maximum number of controlled axes |

Three axes linkage (standard), four simultaneous axes (optional) |

||

|

Resolution of each axis |

µm |

0.4 |

|

|

Minimum drive unit |

µm |

1 |

|

|

Input type |

Touch screen, U disk/Net work transmission |

||

|

Display type |

15" LCD screen (TFT-LCD) |

||

|

Manual control box |

Standard point move (multistage switching) |

||

|

Position command type |

Absolute, incremental dual purpose |

||

|

Drive mode |

Fully digital AC servo |

||

|

Standard accessories (see detailed packing list) |

Machine sizing block, adjustable fixture, machine tool light, filter, liquid level controller, fuse, tool box, instruction manual, grease gun, etc. |

432

432